ERP SOFTWARE FOR INDUSTRIAL MANUFACTURERS & SUPPLIERS

ERP APPLICATIONS FOR SMALL & MIDSIZE INDUSTRIAL MANUFACTURERS & SUPPLIERS

ERP software for industrial manufacturers and suppliers is vital in this day to drive profitable growth and run a smooth operation. Companies often face challenges ranging from complex supply chain management to labor shortages and rising costs. Implementing an Enterprise Resource Planning (ERP) system tailored for machinery manufacturing can be the key to overcoming these hurdles. Learn how ERP solutions effectively address common pain points and support various sub-sectors of industrial product manufacturing and distribution.

HOW A PARTNERSHIP WITH N’WARE HELPED LEWA WITH THEIR COMPLEX MANUFACTURING PROCESSES

LEWA is a precision pump manufacturer based in Germany but also operates three locations in the US. The manufacturer has been using SAP Business One since 2010, which unifies all of the businesses it has acquired over the last five years. The clear, intuitive ERP solution simplifies the firm’s complex processes and provides the flexibility and real-time visibility Lewa-Nikkiso needs to understand its past and plot its course for the future as a unified organization.

COMPREHENSIVE SOLUTIONS FOR INDUSTRIAL MANUFACTURERS & DISTRIBUTORS

COMPREHENSIVE SOLUTIONS FOR INDUSTRIAL MANUFACTURERS & DISTRIBUTORS

Financials & Cost Control

The analytics tools monitor time and cost across the production cycle, enabling manufacturers to spot inefficiencies and implement strategies to optimize spending and lower production costs.

Inventory Management

Accurate inventory management is crucial to avoid overstocking or stockouts. ERP solutions provide real-time tracking of inventory, automated reorder points, and comprehensive forecasting tools.

Real-Time Business Visibility

With business intelligence dashboards updating in real-time, the most important metrics and measures are on hand.

Supply Chain Optimization

ERP software enhances visibility across the supply chain, ensuring real-time updates on raw material availability, supplier performance, and logistics.

WE HELP INDUSTRIAL SUPPLIERS INCREASE THEIR BOTTOM-LINE

Manufacturing of Industrial Equipment

“A company like N’ware is a really valuable partner to us and it’s been really great working with them. One of the things I really like about them is their responsiveness, but also their proactiveness.”

– Tina Reynolds, IT Manager, LEWA-Nikkiso

Manufacturing of Industrial Equipment

“A company like N’ware is a really valuable partner to us and it’s been really great working with them. One of the things I really like about them is their responsiveness, but also their proactiveness.”

– Tina Reynolds, IT Manager, LEWA-Nikkiso

“Anyone could give us a basic ERP solution. But with SAP Business One, we get exposure to a solution that works with clients worldwide. It gives us best-practice insight I can incorporate into our business to help it grow.”

– Prem Abraham, IT Manager, Humboldt Manufacturing

Manufacturing of Industrial Equipment and Components

Manufacturing of Industrial Equipment and Components

“Anyone could give us a basic ERP solution. But with SAP Business One, we get exposure to a solution that works with clients worldwide. It gives us best-practice insight I can incorporate into our business to help it grow.”

– Prem Abraham, IT Manager, Humboldt Manufacturing

Manufacturing of Industrial Equipment and Components

“There are limitless opportunities with SAP, and we’ve been really impressed with the level of customization available. It supports our business, so we’re able to adapt constantly and grow sales year-on-year.”

– Jennifer DiFranco, Controller, GenSwiss

Manufacturing of Industrial Equipment and Components

“There are limitless opportunities with SAP, and we’ve been really impressed with the level of customization available. It supports our business, so we’re able to adapt constantly and grow sales year-on-year.”

– Jennifer DiFranco, Controller, GenSwiss

Manufacturing of Industrial Components

“SAP gives people more power to do their job. Everyone now has an instant overview of all elements related to a project. That’s been a real savings for our company – and would have been extremely time consuming to find out using our previous system.”

– Joanie Malone, Controller, PM International Suppliers

“SAP gives people more power to do their job. Everyone now has an instant overview of all elements related to a project. That’s been a real savings for our company – and would have been extremely time consuming to find out using our previous system.”

– Joanie Malone, Controller, PM International Suppliers

Manufacturing of Industrial Components

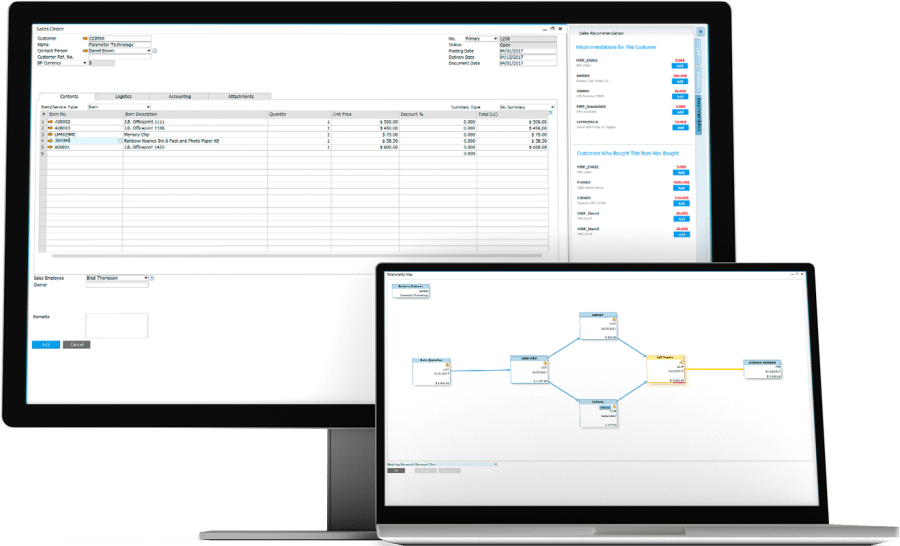

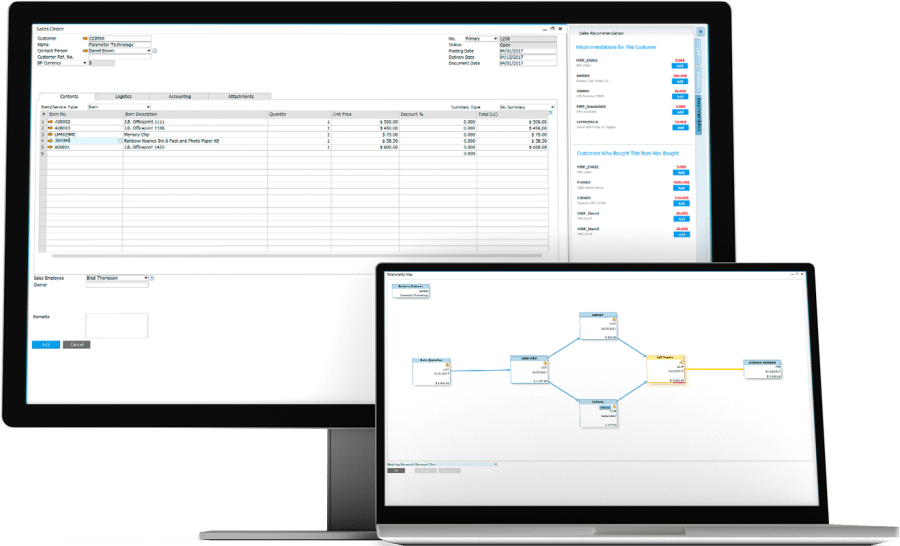

ERP & Business Applications Built for Industrial Manufacturers & Distributors

SAP Business One enhances profitability for industrial manufacturers and suppliers by streamlining operations, optimizing inventory, and improving production planning. Its integrated platform provides real-time insights into costs, facilitates better supply chain management, and enhances sales through improved CRM. Data-driven decision-making, reduced administrative burden, and increased customer satisfaction contribute to overall cost reduction and increased profitability.

ERP & Business Applications Built for Industrial Manufacturers & Distributors

SAP Business One enhances profitability for industrial manufacturers and suppliers by streamlining operations, optimizing inventory, and improving production planning. Its integrated platform provides real-time insights into costs, facilitates better supply chain management, and enhances sales through improved CRM. Data-driven decision-making, reduced administrative burden, and increased customer satisfaction contribute to overall cost reduction and increased profitability.

ESSENTIAL FEATURES

Costs Analysis & Financials

An ERP’s built-in analytics tools track time and cost spends on different aspects of the production cycle. This data allows manufacturers to identify inefficiencies and implement measures to optimize spending and reduce overall production costs.

Material Repair and Overhaul

An ERP software maintains detailed records of repairs, tracks parts used, and logs the time taken for each task. This comprehensive oversight helps manage service timelines effectively and ensures equipment uptime.

Advanced Manufacturing

ERP platforms integrate seamlessly with advanced manufacturing technologies, such as CAD/CAM systems and IoT-enabled machinery. This connectivity allows for real-time data flow, enhancing productivity, precision, and quality control.

Quality Control

A critical aspect of industrial manufacturing is quality assurance. ERP solutions streamline the process by offering built-in quality management modules that track quality checks at various stages of production.

Warehouse Optimization

ERP systems help manufacturers proactively manage equipment maintenance schedules, preventing unexpected breakdowns and ensuring consistent operational efficiency. This predictive maintenance approach minimizes downtime and extends the lifecycle of machinery.

BOM version Control

An ERP system ensures that updates to BOMs are tracked accurately, maintaining version control to prevent costly errors in production. This functionality is particularly valuable when customizations or product variations are frequent.

Planning & Scheduling

ERP solutions facilitate advanced planning and scheduling capabilities, enabling manufacturers and distributors to manage capacity, allocate resources effectively, and plan production runs that align with demand forecasts. This reduces bottlenecks and improves workflow efficiency.

Machine & Apps Connectivity

The ability of ERP software to integrate with manufacturing machines, CAD, and truck scales allows for seamless data collection and monitoring. This capability supports predictive maintenance, real-time adjustments to production processes, and enhanced equipment efficiency.

TRUSTED BY HUNDREDS OF MANUFACTURERS & DISTRIBUTORS ACROSS MULTIPLE INDUSTRIAL SECTORS

TRUSTED BY HUNDREDS OF MANUFACTURERS & DISTRIBUTORS ACROSS MULTIPLE INDUSTRIAL SECTORS

Machinery

Machinery

ERP systems cater specifically to the needs of machinery manufacturers by providing robust project management, BOM management, and quality assurance modules. This brings improved production quality, reduced operational errors, and better warranty handling.

Parts & Components

Parts & Components

Manufacturers of machine parts benefit more specifically from ERP solutions that manage intricate BOMs, track material usage, and streamline the supply chain. These features ensure timely delivery and reduce waste, improving the bottom line.

Tools & Equipment

Tools & Equipment

For companies producing specialized tools and equipment, an ERP simplifies inventory management and production scheduling, optimizing resource use and supports tracking warranties and managing MRO tasks to enhance product lifecycle management.

Semiconductors

Semiconductors

Due to the complexity and precision needed in semiconductor manufacturing, rigorous planning and quality control are essential. ERP solutions helps with integrated quality checks, real-time data, and robust scheduling tools to ensure high standards and meet timelines.

Building Materials

Building Materials

Manufacturers of building materials face challenges in supply chain logistics and compliance. ERP systems streamline operations by offering improved visibility into supply chain processes, enhanced planning tools, and compliance management to meet regulatory standards.

RELATED DOWNLOADS

SAP BUSINESS ONE

LISA WMS

Creatio CRM