ERP SOFTWARE FOR FOOD AND BEVERAGE WHOLESALE DISTRIBUTORS AND MANUFACTURERS

ERP APPLICATIONS FOR THE FOOD & BEVERAGES INDUSTRY

In today’s fast-paced food and beverage industry, staying competitive requires more than just good products. Businesses across the supply chain—whether in manufacturing, processing, distribution, or packaging—must efficiently manage operations to maintain profitability and ensure compliance with stringent regulations. This is where Enterprise Resource Planning (ERP) software becomes indispensable.

SAP Business One is specifically designed to address the unique challenges of the food and beverage sector. From streamlining supply chains to ensuring regulatory compliance and quality control, it empowers businesses to operate more effectively, reduce costs, and scale effortlessly. Let’s explore how ERP solutions transform the operations of food and beverage businesses while tackling their most pressing pain points.

How a Partnership with N’ware Helped Boston Organics Grow

Boston Organics used several systems and databases to manage their clients, inventory and deliveries, which over the years became highly inefficient and didn’t allow for improvements in their business model. The flexibility and adaptability provided by SAP Business One allows them to grow as they continue to offer fresh, organic produce to their customers.

KEY BENEFITS OF ERP FOR THE FOOD & BEVERAGE INDUSTRIES

Industry challenge

Supply Chain Complexities

Managing the dynamic and ever-changing nature of the food and beverage supply chain—marked by its unique challenges such as short product lifecycles, highly variable seasonal demand, and frequent fluctuations in supply chain logistics—can be an immensely complex and often overwhelming task. Businesses operating in this space must constantly adapt to evolving market trends, shifts in consumer preferences, and unpredictable disruptions, such as adverse weather conditions, supplier delays, or regulatory changes.

How SAP Business One helps

- Real-time Visibility: ERP systems offer live data on inventory, supplier performance, and delivery schedules, enabling businesses to respond quickly to supply chain disruptions.

- Enhanced Forecasting: With predictive analytics, businesses can anticipate demand and adjust procurement accordingly, minimizing excess inventory and shortages.

- Streamlined Operations: ERP integrates processes like order management, shipping, and procurement into a single platform, reducing delays and inefficiencies.

Growth and Scalability

As businesses grow, manual systems or siloed software often become inadequate to manage increased demands. Expanding product lines, entering new markets, and managing higher transaction volumes require robust systems.

- Scalable Infrastructure: ERP systems are designed to grow with your business, accommodating additional users, data, and functionalities.

- Centralized Data Management: By consolidating all business data in one place, ERP allows seamless communication between departments, supporting smoother operations during periods of growth.

Lack of Integration

Software silos—where different systems work independently—can lead to data inconsistencies, inefficiencies, and a lack of clear visibility across operations.

- Unified Platform: ERP replaces disparate systems with a single, integrated solution, ensuring all departments access and share consistent data.

- Improved Collaboration: Teams across accounting, sales, production, and distribution can work together effectively, enhancing overall productivity.

Regulatory Compliance and Reporting

Food and beverage businesses face stringent regulations around safety, labeling, and traceability, requiring detailed records and the flexibility to adapt to changes. Effective compliance is essential to avoid penalties, maintain brand reputation, and ensure transparency throughout the supply chain.

- Automated Compliance Tracking: ERP systems monitor regulatory requirements, flagging updates and automating the generation of compliance reports.

- Traceability Features: ERPs track raw materials and finished goods throughout the supply chain, simplifying lot tracking and recall management, and ensuring regulatory adherence.

Quality Assurance and Control

Maintaining high-quality standards, preventing recalls, and ensuring product safety are vital in the food and beverage industry. This requires strict safety protocols, thorough quality control, and careful oversight of sourcing, production, and distribution to protect consumers and uphold brand trust.

- Proactive Quality Management: ERP monitors quality checks at every stage of production, helping identify and address issues before they escalate.

- Recall Management: With detailed traceability, businesses can efficiently manage recalls, protecting both customers and brand reputation.

Inventory Management and Avoiding Food Spoilage

Perishable inventory demands precise tracking to prevent waste and optimize storage.

- Inventory Insights: ERP provides real-time data on stock levels, expiration dates, and inventory turnover rates, reducing food spoilage.

- Optimized Storage: By analyzing trends, businesses can adjust procurement and storage practices to maximize efficiency.

WE HELP FOOD & BEVERAGES MANUFACTURERS INCREASE THEIR BOTTOM-LINE

Distribution of Food & Beverages

“SAP gave us some right out-of-the-box functionality and was flexible enough to customize certain aspects of it that allowed us to maintain the uniqueness of our business.”

– Jeffrey Barry, President, Boston Organics

“The move to SAP Business One has helped to streamline the company’s management tools by eliminating parallel systems and automating and framing many previously manual tasks.”

– Vincent Fournier, CFO, Glutenberg

Manufacturing & Distribution of Food & Beverages

Distribution of Food & Beverages

“LISA is a robust solution but simple and easy to use at the same time. We evolved from a totally manual process to a paperless scenario with LISA WMS.”

– David Cintrón, IT Director, SuperMax

WE HELP FOOD & BEVERAGES MANUFACTURERS INCREASE THEIR BOTTOM-LINE

Distribution of Food & Beverages

“SAP gave us some right out-of-the-box functionality and was flexible enough to customize certain aspects of it that allowed us to maintain the uniqueness of our business.”

– Jeffrey Barry, President, Boston Organics

Manufacturing & Distribution of Food & Beverages

“The move to SAP Business One has helped to streamline the company’s management tools by eliminating parallel systems and automating and framing many previously manual tasks.”

– Vincent Fournier, CFO, Glutenberg

Distribution of Food & Beverages

“LISA is a robust solution but simple and easy to use at the same time. We evolved from a totally manual process to a paperless scenario with LISA WMS.”

– David Cintrón, IT Director, SuperMax

ERP & Business Applications Built for Food & Beverage Manufacturers and Distributors

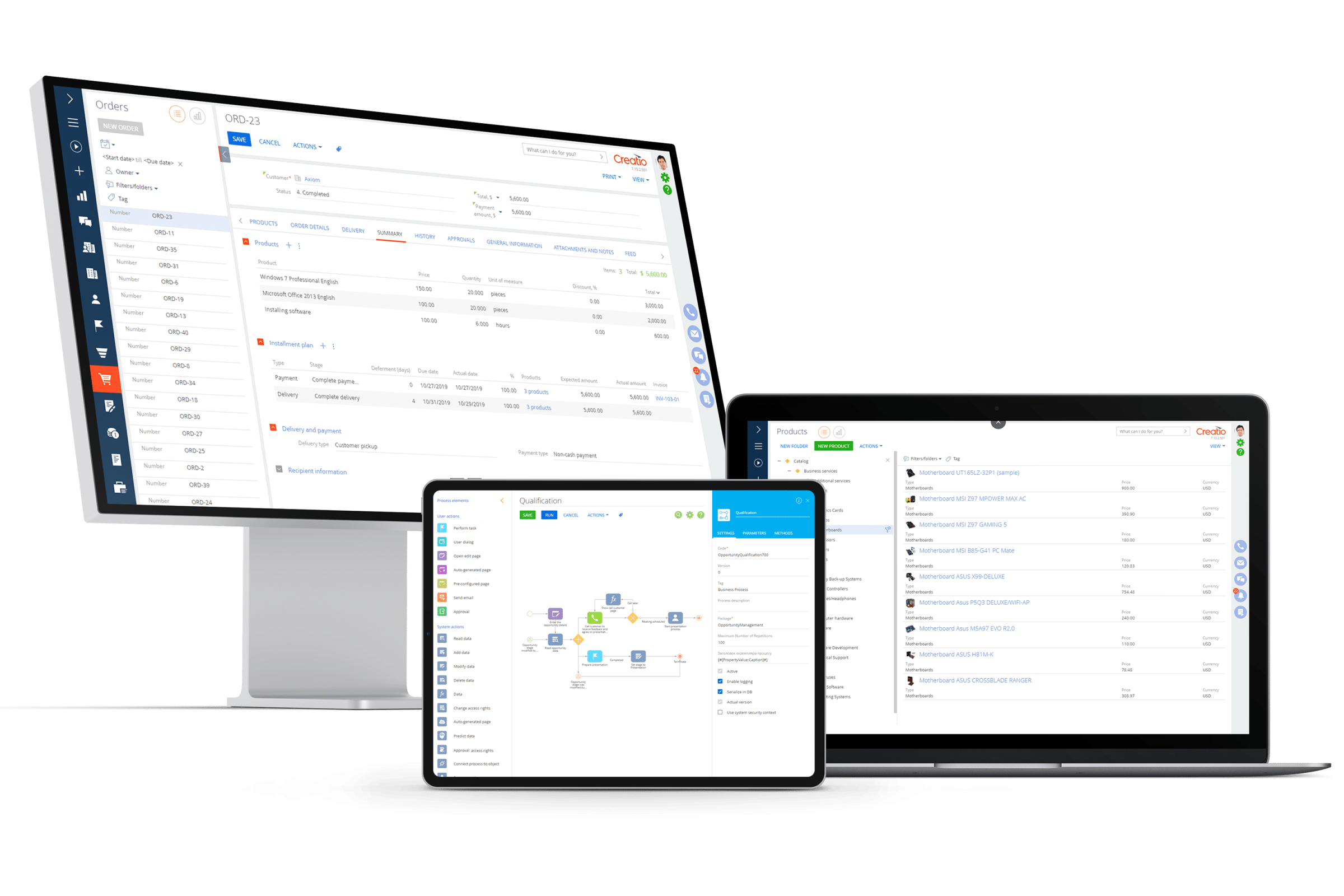

SAP Business One enhances profitability for food & beverage manufacturers and distributors by streamlining operations, optimizing inventory, and improving production planning. Its integrated platform provides real-time insights into costs, facilitates better supply chain management, and enhances sales through improved CRM. Data-driven decision-making, reduced administrative burden, and increased customer satisfaction contribute to overall cost reduction and increased profitability.

ERP & Business Applications Built for Food & Beverage Manufacturers and Distributors

SAP Business One enhances profitability for food & beverage manufacturers and distributors by streamlining operations, optimizing inventory, and improving production planning. Its integrated platform provides real-time insights into costs, facilitates better supply chain management, and enhances sales through improved CRM. Data-driven decision-making, reduced administrative burden, and increased customer satisfaction contribute to overall cost reduction and increased profitability.

INDUSTRY-SPECIFIC APPLICATIONS OF ERP SOLUTIONS

Brewery, Wine & Distillery

Brewery, Wine & Distillery

Brewery, winery, and distillery operations are highly regulated and involve complex production processes. These businesses must manage precise recipes, track inventory accurately, and comply with strict safety, labeling, and traceability standards. Balancing these demands, along with supply chain fluctuations and seasonal variations, can be challenging. SAP Business One supports these operations by :

- Providing enhanced scalability for expanding product lines.

- Offering improved control over raw material quality and costs.

- Giving simplified logistics for distribution and retail partnerships.

Food Preparation & Packaging

Food Preparation & Packaging

Food preparation and packaging companies bridge the gap between raw ingredient producers and retailers, managing fast-moving workflows and ensuring products are ready for distribution on tight timelines. ERP solutions help manage these complexities by offering:

- Optimized use of raw materials to reduce costs.

- Improved compliance with food labeling regulations.

- Enhanced inventory management to prevent bottlenecks in production.

- Tracking of customer and supplier rebates and special offers

- Recipe management

Agriculture

Agriculture

Agricultural businesses are at the foundation of the food and beverage supply chain, facing challenges like unpredictable weather, fluctuating demand, and the need for sustainable practices. SAP Business One can modernize farm operations, enabling greater efficiency and profitability by providing:

- Enhanced sustainability through resource-efficient practices.

- Greater visibility across farm operations for improved decision-making.

- Seamless integration with distributors and processors for a streamlined supply chain.

ESSENTIAL FEATURES

Costs Analysis & Financials

An ERP’s built-in analytics tools track time and cost spends on different aspects of the production cycle. This data allows manufacturers to identify inefficiencies and implement measures to optimize spending and reduce overall production costs.

Material Repair and Overhaul

An ERP software maintains detailed records of repairs, tracks parts used, and logs the time taken for each task. This comprehensive oversight helps manage service timelines effectively and ensures equipment uptime.

Advanced Manufacturing

ERP platforms integrate seamlessly with advanced manufacturing technologies, such as CAD/CAM systems and IoT-enabled machinery. This connectivity allows for real-time data flow, enhancing productivity, precision, and quality control.

Quality Control

A critical aspect of industrial manufacturing is quality assurance. ERP solutions streamline the process by offering built-in quality management modules that track quality checks at various stages of production.

Warehouse Optimization

ERP systems help manufacturers proactively manage equipment maintenance schedules, preventing unexpected breakdowns and ensuring consistent operational efficiency. This predictive maintenance approach minimizes downtime and extends the lifecycle of machinery.

BOM version Control

An ERP system ensures that updates to BOMs are tracked accurately, maintaining version control to prevent costly errors in production. This functionality is particularly valuable when customizations or product variations are frequent.

Planning & Scheduling

ERP solutions facilitate advanced planning and scheduling capabilities, enabling manufacturers and distributors to manage capacity, allocate resources effectively, and plan production runs that align with demand forecasts. This reduces bottlenecks and improves workflow efficiency.

Machine & Apps Connectivity

The ability of ERP software to integrate with manufacturing machines, CAD, and truck scales allows for seamless data collection and monitoring. This capability supports predictive maintenance, real-time adjustments to production processes, and enhanced equipment efficiency.

RELATED DOWNLOADS

SAP BUSINESS ONE

LISA WMS

Creatio CRM