ERP SOFTWARE FOR THE AUTOMOTIVE AFTERMARKET INDUSTRY

ERP Solutions for a Competitive Automotive Aftermarket

In the automotive aftermarket industry, managing inventory, streamlining production, ensuring accurate financials, and optimizing the supply chain are ongoing challenges. From handling replacement parts to managing accessories and specialty equipment, businesses must adapt to ever-changing customer demands while maintaining efficiency and profitability. SAP Business One provides a comprehensive solution for these challenges, helping automotive aftermarket companies stay competitive and organized.

With advanced features such as real-time analytics, warehouse management systems (WMS) like LISA WMS, and eCommerce integration, SAP Business One can simplify operations, reduce errors, and improve overall performance. Let’s explore how ERP software helps manage key pain points in inventory, production, supply chain, sales, and financials for the automotive aftermarket industry.

How N’ware created Value for Nemesis

Nemesis’ management team chose SAP Business One which was fulfilling most of their financial and operational requirements, but as a leading wholesale distribution company with international partners, they needed more advanced warehouse management features. Thanks to SAP Business One and LISA WMS, Nemesis’ management team is confident they have the tools to grow on the international marketplace.

KEY BENEFITS OF ERP FOR THE AUTOMOTIVE AFTERMARKET INDUSTRY

Industry challenge

Inventory Management

Efficient inventory management is a cornerstone of success for automotive aftermarket businesses, which often handle a diverse range of replacement parts, accessories, and specialty equipment. Managing thousands of SKUs, handling seasonal demand fluctuations, and ensuring accurate stock levels are crucial for automotive aftermarket businesses dealing with replacement parts, accessories, and specialty equipment. Poor inventory management can lead to stockouts, overstocking, and dissatisfied customers.

How SAP Business One helps

- Real-Time Analytics and Forecasting: Up-to-the-minute data on inventory levels, allowing you to forecast demand accurately and make data-driven purchasing decisions.

- Full Product Tracking and Traceability: Track every part or accessory from procurement to delivery, ensuring complete transparency and reducing the risk of errors.

- Warehouse Management Systems (LISA WMS): Advanced WMS like LISA streamline warehouse operations by automating picking, packing, and shipping processes, improving accuracy and reducing lead times.

Production Planning

Production planning is a critical process for businesses involved in manufacturing specialty equipment or custom parts. These operations often require a high degree of flexibility and precision to accommodate unique customer requirements, while minimizing production downtime requires precise scheduling and coordination.

- Real-Time Analytics: Gain insights into production schedules, raw material availability, and labor capacity.

- Web & Carrier Integration: Seamlessly connect production schedules with shipping and logistics data to maintain transparency.

- Traceability: Track components throughout the production process to ensure quality control and compliance.

Supply Chain Management

In the fast-paced world of automotive aftermarket operations, effective supply chain management is essential to ensure smooth and timely delivery. Supply chain disruptions, delayed deliveries, and supplier inconsistencies can significantly impact business performance, leading to production delays, increased costs, and customer dissatisfaction. Reliable supply chain management is critical.

- Web & Carrier Integration: ERP systems integrate with web portals and shipping carriers, giving you a clear picture of how operations are running and where potential bottlenecks exist.

- Real-Time Analytics: Monitor supplier performance and delivery times to make informed decisions and minimize disruptions.

- Supplier Rebates Tracking: Automate and manage supplier rebates, ensuring you never miss out on opportunities for cost savings.

Sales and Customer Interactions

In the competitive automotive aftermarket industry, exceptional customer service is not just a value-add—it’s a crucial differentiator that can set a business apart from its competitors. Whether you’re selling replacement parts, accessories, or specialty equipment, efficient sales processes and responsive customer support are essential.

- eCommerce with ERP Integration: Seamlessly integrate your online store with ERP software to ensure accurate inventory availability, real-time order tracking, and prompt order fulfillment.

- Real-Time Data: Empower your sales team with real-time customer data, order histories, and product availability to provide better service.

- Full Product Traceability: Provide customers with accurate information on order status and delivery times, improving trust and satisfaction.

Financials and Accounting

Managing financial operations in the automotive aftermarket industry requires meticulous oversight and precision. From tracking sales revenue and processing supplier payments to managing customer rebates and monitoring overall profitability, financial management plays a central role in business success. Manual processes often lead to errors and inefficiencies.

- Real-Time Analytics: Get instant access to financial data, helping you monitor cash flow, expenses, and profitability.

- Rebate Tracking: Automatically track customer and supplier rebates, ensuring accurate calculations and timely payouts.

- Integrated Financial Management: ERP systems integrate accounting with inventory, sales, and production data, reducing manual entry and errors.

WE HELP MANY AUTOMOTIVE AFTERMARKET COMPANIES WITH THEIR OPERATIONS

Supply Chain & Logistics for Electronics & Automotive

“Using SAP and LISA combined, we’ve definitely seen efficiencies in our warehousing and our whole logistics. We’re definitely faster and leaner; we can now grow and scale with the current infrastructure.”

– Chris Chance, Warehouse Operations Manager, Nemesis

“We now have complete visibility and control of the many data points required to service our customers. We have extended our cut-off time for orders, increased our business and strengthened our customer relationship, thanks to our new technology.”

– David Wilhite, President, Neotek Corporation

Manufacturing & Distribution of Automotive parts

Manufacturing of Automotive parts

“SAP Business One is a great tool. It brings the knowledge and structure of a large system to SMBs, so we can implement our policies and processes in the right way.”

– Andrew Failie, VP Operations and Admin, Trux Accessories

WE HELP MANY AUTOMOTIVE AFTERMARKET COMPANIES WITH THEIR OPERATIONS

Supply Chain & Logistics for Electronics & Automotive

“Using SAP and LISA combined, we’ve definitely seen efficiencies in our warehousing and our whole logistics. We’re definitely faster and leaner; we can now grow and scale with the current infrastructure.”

– Chris Chance, Warehouse Operations Manager, Nemesis

Manufacturing & Distribution of Automotive parts

“We now have complete visibility and control of the many data points required to service our customers. We have extended our cut-off time for orders, increased our business and strengthened our customer relationship, thanks to our new technology.”

– David Wilhite, President, Neotek Corporation

Manufacturing of Automotive parts

“SAP Business One is a great tool. It brings the knowledge and structure of a large system to SMBs, so we can implement our policies and processes in the right way.”

– Andrew Failie, VP Operations and Admin, Trux Accessories

ERP & Business Applications Built for Automotive Aftermarket Manufacturers and Distributors

SAP Business One enhances profitability for automotive aftermarket manufacturers and distributors by streamlining operations, optimizing inventory, and improving production planning. Its integrated platform provides real-time insights into costs, facilitates better supply chain management, and enhances sales through improved CRM. Data-driven decision-making, reduced administrative burden, and increased customer satisfaction contribute to overall cost reduction and increased profitability.

ERP & Business Applications Built for Automotive Aftermarket Manufacturers and Distributors

SAP Business One enhances profitability for automotive aftermarket manufacturers and distributors by streamlining operations, optimizing inventory, and improving production planning. Its integrated platform provides real-time insights into costs, facilitates better supply chain management, and enhances sales through improved CRM. Data-driven decision-making, reduced administrative burden, and increased customer satisfaction contribute to overall cost reduction and increased profitability.

HOW ERP BENEFITS DIFFERENT SUB-SECTORS OF THE AUTOMOTIVE AFTERMARKET

Replacement Parts

Replacement Parts

Managing vast inventories of replacement parts, ensuring timely delivery, and maintaining strong supplier relationships are critical challenges for businesses in the automotive aftermarket industry. The complexity of these operations requires a robust system to keep everything organized and efficient. ERP can help with:

- Inventory Optimization: Real-time inventory management ensures you have the right parts in stock when needed.

- Traceability: Track parts from supplier to customer, ensuring quality and reducing returns.

- Supplier Management: Streamline supplier interactions and rebates for cost savings.

Accessories

Accessories

For businesses focused on automotive accessories, keeping up with rapidly changing trends and evolving customer demands is essential to staying competitive. From new styles and features to seasonal preferences and emerging technologies, the market requires businesses to remain agile and responsive. SAP Business One can help by providing :

- eCommerce Integration: Sync your online store with ERP for accurate inventory and order management.

- Production Planning: Ensure popular accessories are produced and delivered efficiently.

- Customer Insights: Use real-time data to anticipate trends and personalize offerings.

Specialty Equipment

Specialty Equipment

Manufacturing specialty equipment in the automotive aftermarket industry often involves handling custom orders and managing complex production processes, requiring precision and adaptability at every stage. ERP software is a critical tool for streamlining these operations :

- Production Scheduling: Plan production with precision to ensure that custom orders are completed on time and to specification.

- Supply Chain Visibility: Ensure that essential components are available when needed, minimizing delays and keeping production on schedule.

- Financial Accuracy: Track custom orders and associated costs for accurate billing.

ESSENTIAL FEATURES

Costs Analysis & Financials

An ERP’s built-in analytics tools track time and cost spends on different aspects of the production cycle. This data allows manufacturers to identify inefficiencies and implement measures to optimize spending and reduce overall production costs.

Material Repair and Overhaul

An ERP software maintains detailed records of repairs, tracks parts used, and logs the time taken for each task. This comprehensive oversight helps manage service timelines effectively and ensures equipment uptime.

Advanced Manufacturing

ERP platforms integrate seamlessly with advanced manufacturing technologies, such as CAD/CAM systems and IoT-enabled machinery. This connectivity allows for real-time data flow, enhancing productivity, precision, and quality control.

Quality Control

A critical aspect of industrial manufacturing is quality assurance. ERP solutions streamline the process by offering built-in quality management modules that track quality checks at various stages of production.

Warehouse Optimization

ERP systems help manufacturers proactively manage equipment maintenance schedules, preventing unexpected breakdowns and ensuring consistent operational efficiency. This predictive maintenance approach minimizes downtime and extends the lifecycle of machinery.

BOM version Control

An ERP system ensures that updates to BOMs are tracked accurately, maintaining version control to prevent costly errors in production. This functionality is particularly valuable when customizations or product variations are frequent.

Planning & Scheduling

ERP solutions facilitate advanced planning and scheduling capabilities, enabling manufacturers and distributors to manage capacity, allocate resources effectively, and plan production runs that align with demand forecasts. This reduces bottlenecks and improves workflow efficiency.

Machine & Apps Connectivity

The ability of ERP software to integrate with manufacturing machines, CAD, and truck scales allows for seamless data collection and monitoring. This capability supports predictive maintenance, real-time adjustments to production processes, and enhanced equipment efficiency.

RELATED DOWNLOADS

SAP BUSINESS ONE

LISA WMS

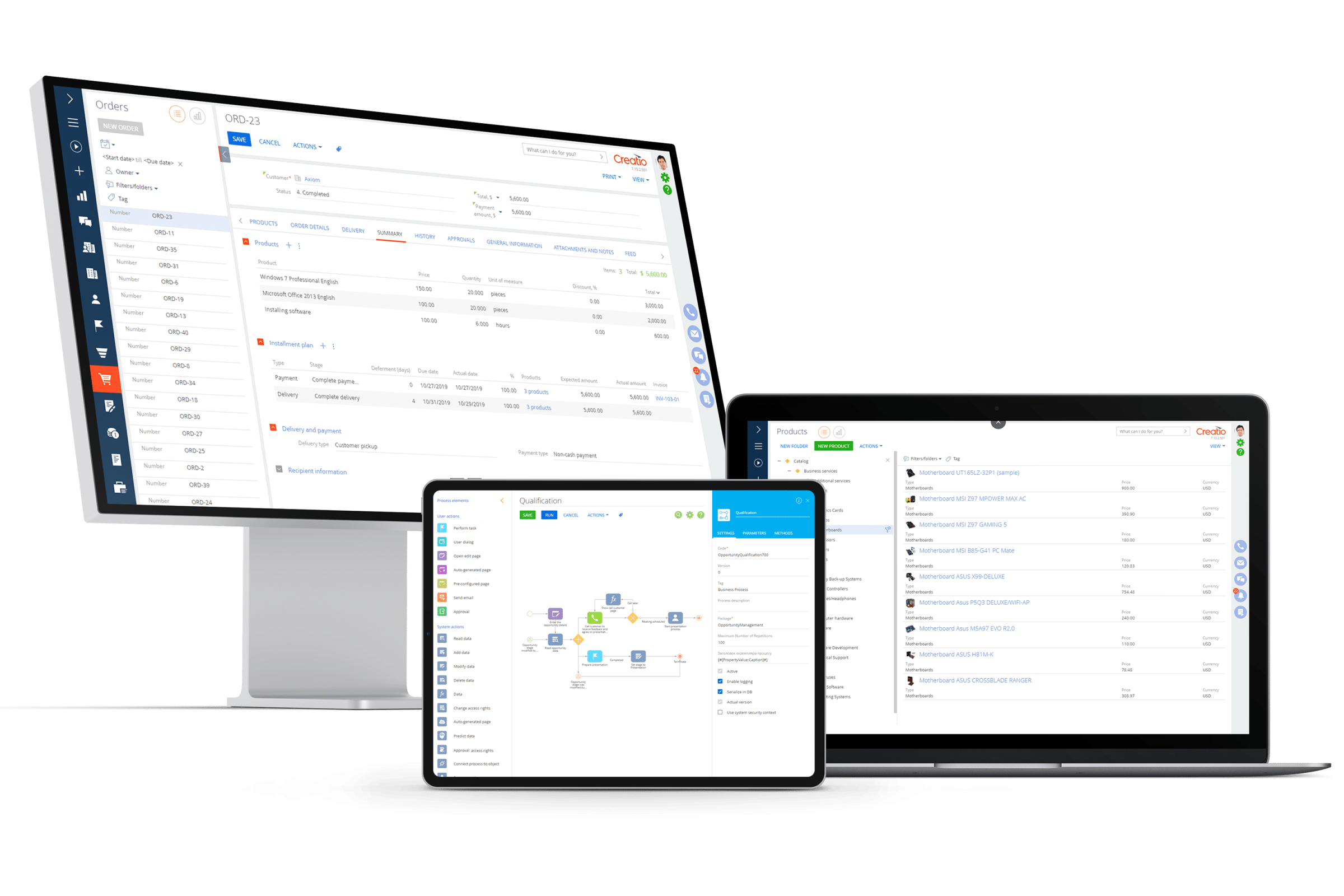

Creatio CRM